In today’s competitive market, surface quality and finishing standards matter more than ever. Whether in manufacturing, construction, or design, the final look and function of a product determine its usability and value. That’s where the term acamento comes into play. Originating from industrial and design terminology, acamento refers to the finishing process that refines a product’s surface, enhances durability, and boosts aesthetic appeal. It has become a crucial factor in quality assurance and brand perception.

The Origins and Evolution of Acamento

The word acamento has its roots in Latin-derived languages like Portuguese and Spanish, often used in contexts meaning “finishing” or “completion.” While it initially referred to construction finishes like flooring or painting, the term has evolved to include technological, architectural, mechanical, and design processes. In modern industry, acamento is no longer just about looks—it’s about functionality, safety, and precision.

Applications of Acamento Across Industries

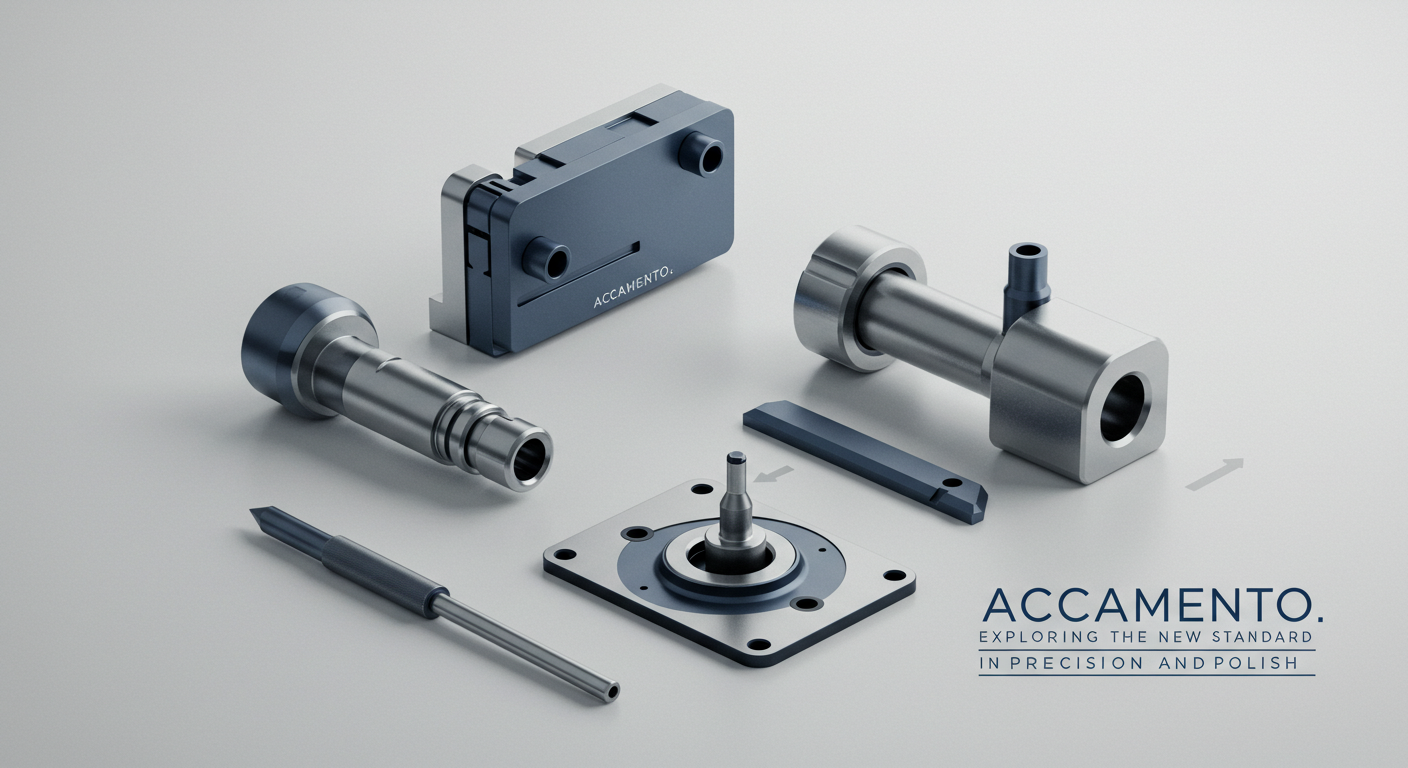

1. Manufacturing and Metalwork

In sectors like automotive or aerospace, acamento involves precision grinding, polishing, coating, and surface treatment. These finishes improve:

-

Corrosion resistance

-

Surface friction control

-

Aesthetic appeal

-

Structural integrity

For instance, turbine blades and engine parts undergo advanced acamento procedures to ensure optimal aerodynamic performance.

2. Interior and Architectural Design

In the design world, acamento refers to the final treatment applied to surfaces like walls, ceilings, and flooring. Popular examples include:

-

Wood varnishing

-

Marble polishing

-

Matte or glossy paint finishes

-

Textured concrete coatings

Good acamento enhances not just beauty, but long-term maintenance and material protection.

3. Consumer Electronics and Gadgets

Every smartphone or laptop finish you admire results from carefully engineered acamento. Whether it’s a brushed aluminum look, a matte plastic case, or a scratch-resistant screen, acamento plays a vital role in usability, durability, and visual design.

Benefits of High-Quality Acamento

Understanding the importance of acamento can give you a competitive edge in product design or project execution. Here are some of its main benefits:

1. Enhanced Aesthetics

Well-finished surfaces leave a lasting impression. Whether it’s a luxury car dashboard or a polished kitchen countertop, acamento brings products to life visually.

2. Improved Durability

Finishes protect materials from moisture, chemicals, UV exposure, and wear and tear. This extends the product’s lifecycle, lowering replacement costs.

3. Better User Experience

Tactile surfaces matter. Smooth finishes feel good to the touch, while matte or textured finishes reduce fingerprints or improve grip.

4. Regulatory Compliance

Certain industries require acamento processes to meet health, safety, and environmental standards, especially in pharmaceuticals, food production, and electronics.

Types of Acamento Techniques

Acamento isn’t a one-size-fits-all process. It varies based on industry, purpose, and material type. Here are a few popular techniques:

-

Polishing – Used for metals, wood, or stones to achieve a smooth or reflective surface.

-

Anodizing – Common in aluminum products for corrosion protection and color variation.

-

Powder Coating – A dry finishing method used to create a durable outer layer.

-

Laser Etching – Adds texture or patterns for branding or functional purposes.

-

Laminating – Often used in furniture and flooring for protective top layers.

Each acamento method can be tailored to meet specific aesthetic or functional requirements.

Sustainability and Eco-Friendly Acamento

With growing environmental concerns, sustainable practices are gaining momentum. These include:

-

Using water-based paints and coatings

-

Adopting low-emission solvents

-

Recycling materials during finishing

-

Reducing waste through precision automation

Eco-friendly acamento not only helps the planet but also appeals to conscious consumers, giving brands a competitive advantage.

Acamento in Modern Product Design

Designers and engineers are increasingly integrating acamento during the early planning stages. Instead of treating it as a last-minute process, they factor it into:

-

Material selection

-

Component assembly

-

User interface

-

Ergonomics

In high-end products, the acamento process can define the entire brand identity, such as the sleek feel of Apple products or the rugged texture of outdoor gear.

Challenges in Achieving Flawless Acamento

While acamento offers numerous benefits, it also comes with challenges:

-

High costs for premium finishes

-

Time-consuming processes

-

Skilled labor requirements

-

Inconsistencies due to material variations

These hurdles can be managed with advanced tools, trained technicians, and quality control measures.

Future Trends in Acamento

As industries innovate, so does the acamento process. Here are future trends to watch:

-

Nano-coatings for enhanced resistance to microbes and scratches

-

3D printed surface treatments for unique textures

-

AI-driven acamento quality checks

-

Customizable user-selected finishes

The future of lies in combining technology, sustainability, and personalization to meet evolving consumer demands.

Conclusion: The Lasting Impact of Acamento

is no longer a finishing touch—it’s a defining aspect of product performance and perception. From safeguarding durability to elevating aesthetics, is at the heart of every successful product or project. Whether you’re a manufacturer, architect, or designer, integrating strategically can significantly improve quality and satisfaction. As innovation continues, expect to become smarter, greener, and more customizable.